1. Front trunion,

Polish made

2. Bolt Carrier,

Polish made

3. Bolt, Polish made

4. Gas Piston, Polish

made

5. Buttstock, Polish

made

6. Pistol Grip,

Polish made

7. Upper and Lower

Handguards (Both count as 1 part), Polish made

8. Barrel, US made,

AK Builder #H1-31

9. Receiver, US made

from AK Builder flat, #B1-71

10. Muzzle Device, US

made, Tapco #AK0684

11. Hammer, US made,

Tapco #AK0650single

12. Trigger, US made,

Tapco #AK0650single

13. Disconnector, US

made, Tapco #AK0650single

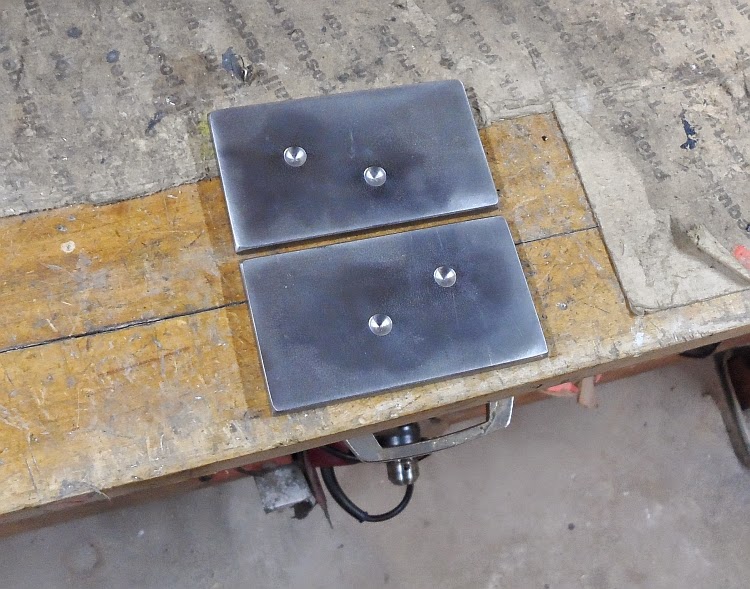

14. Magazine Body, US

made, Tapco #MAG0632

15. Magazine Follower,

US made, Tapco #MAG0632

16. Magazine

Floorplate, US made, Tapco #MAG0632

Interestingly, it's only with rifles that it matters. Pistols and shotguns don't need to follow 922r no matter their origin. If I had made the receiver so that a buttstock couldn't be mounted it would qualify as a pistol and even though it's the exact same gun, I wouldn't need to worry about 922r(or the 16" minimum barrel length rule for that matter).

Interestingly, it's only with rifles that it matters. Pistols and shotguns don't need to follow 922r no matter their origin. If I had made the receiver so that a buttstock couldn't be mounted it would qualify as a pistol and even though it's the exact same gun, I wouldn't need to worry about 922r(or the 16" minimum barrel length rule for that matter).