With my lower printed it's time to fit everything. Everything in the CAD file is pretty much drawn to size, which means that in the physical print, everything has slightly too much material. I'd rather have too much than not enough so I'll leave it like that, but it does mean that the lower will require a little fitting. All the holes get cleaned up with appropriate sized dill bits, and any burrs or bumps where other parts fit need to be filed smooth. I left the surfaces where upper sits on the lower slightly too big in the CAD so that I could get a perfect zero slop fit between the upper and lower(particularly in the buffer tower area), and that also means that there should be enough material to make it fit well with any brand of upper. This makes it less plug and play than a standard AR lower, but the end result is a better fitting part. I also slightly redesigned the trigger transfer lever to make it stronger as a printed part. If it were made from metal, the original 1/4" x 1/4" size will still work fine.

With the lower assembled, I could mock up all the rest of the parts I have on hand. I'm using a Bear Creek 16" stainless barrel, with a matching cheap e-bay muzzle brake(which may not do much, I mostly just like how it looks). I'm using a Yankee Hill low profile gas block installed backwards so that the gas port on the barrel is covered(and the YHM was the cheapest one I could find). A standard barrel nut holds the barrel on, and my yet to be designed handguard will clamp around it. It will be a free floating guard, but if it seems like it needs support, I'll tap the tube hole in the gas block for a front mounting screw. The scope is a 3x9 that my Dad had laying around, and the magazine is a 10 round AR Stoner(actually made by ASC, and reported to feed the 7.62x39 reliably). I'm waiting on a set of screw together anti-walk pins for the trigger and transfer bar, and I still have a lot of work to do for the furniture, but it actually kind of looks like a gun now.

Tuesday, December 31, 2019

It is as easy as it looks, mostly.

You know, any time anybody finds out you have a 3D printer, the very first thing they almost always ask is "Have you printed a gun?" Well, now I can actually say yes. I mean, I've printed several TV/movie costume prop guns for friends, but never anything actually usable. And while this isn't a complete firearm, it qualifies as such on an AR based rifle. I got my SCR lower CAD file updated to where I wanted it, threw it in Cura, and hit print. 16 hours later, here's what I had:

I'm using eSun PLA+, and I chose grey for this project. I will probably eventually reprint it in black after it's tested and proven, but for now the grey will show any cracks or wear very well. I recently watched a Youtube series from CNC Kitchen where he did a bunch of tests showing how print settings can affect print strength, and I recommend that everyone who has a printer go through and watch them. Using his videos as a guideline, I'm using .16mm layer heights, 8 walls, 99% infill, .45mm line width, and 75% fan at 220°C/60°C bed. I almost never use a brim, but I chose to here because every now and then a completely solid(or at least 99% solid) part pull off the bed.

It took an hour or so to get the supports off. I'm not satisfied with how it looks. Because of the way I had to place it diagonally on the print bed to fit my printer, there is a lot of banding in it. Overstuffing the line width like I did (.45mm line width extruding from a .4mm nozzle) helps make the print stronger, but also exaggerates the look of the banding. It's not the prettiest, but it should be strong and functional.

I'm using eSun PLA+, and I chose grey for this project. I will probably eventually reprint it in black after it's tested and proven, but for now the grey will show any cracks or wear very well. I recently watched a Youtube series from CNC Kitchen where he did a bunch of tests showing how print settings can affect print strength, and I recommend that everyone who has a printer go through and watch them. Using his videos as a guideline, I'm using .16mm layer heights, 8 walls, 99% infill, .45mm line width, and 75% fan at 220°C/60°C bed. I almost never use a brim, but I chose to here because every now and then a completely solid(or at least 99% solid) part pull off the bed.

It took an hour or so to get the supports off. I'm not satisfied with how it looks. Because of the way I had to place it diagonally on the print bed to fit my printer, there is a lot of banding in it. Overstuffing the line width like I did (.45mm line width extruding from a .4mm nozzle) helps make the print stronger, but also exaggerates the look of the banding. It's not the prettiest, but it should be strong and functional.

Saturday, December 28, 2019

Stuff that matters

This is the part of projects like this that I like the least, modifying parts that I actually paid for. Though I pretend to know what I'm doing, I'm pretty much making it up as I go along and I'm never certain anything is actually going to work. With the printed stuff it doesn't really matter, cut, grind, file, and if I do it wrong I can just reprint it and I'm not really out much except time. But now I'm to the part where if I screw something up I actually have to buy another one(and pay shipping, and wait a week).

I'm using a side charging 7.62x39 upper receiver and BCG unit from Bear Creek. It's inexpensive, and to my untrained eye looks to be decent quality. The problem is that the bolt carrier is too long since I don't have a buffer tube for it to slide into. Fortunately, the tail of an AR bolt carrier doesn't really do much to stabilize the bolt, all the tight clearance sliders where it contacts the upper receiver are on the front section. So out comes the cutoff wheel. A few whacks and some cleanup with a flap wheel, and our bolt carrier is a much more convenient size.

While it was all apart, I did some work on the firing pin too. Google says that 7.62x39 doesn't always fire reliably in AR platforms, especially the harder primer Russian steel cased stuff that I use. One fix is a heavier hammer spring, but that can negatively affect trigger pull. The other fix is to use an "enhanced" firing pin. What's the difference between the standard and enhanced firing pin? The stop shoulder is .010" shorter on the enhanced pin so that the firing pin protrudes just a little but further. If you don't have any size reference, .010" is about three sheets of paper thick. That little bit can make all the difference in the world on X39 ARs. Enhanced firing pins are cheap, but why spend $10 when I don't have to? The left side of the line is what we need to take off:

You don't even need any special tools to do this. You'd think a firing pin would be too hard to file, but they aren't. Just chuck it in a drill and have at it with a file. It's a 5 minute process.

While I had the grinder out, I cut off the trigger bit of the front trigger. It doesn't need to be cut all the way off, just far enough so that it doesn't hit the inside of the receiver.

Once I've verified that everything works and have uploaded my files, if you want make one yourself here's where the tail of the trigger is cut. The angle isn't super critical and I just used some scribed lines to cut it:

At the request of a guy I know, here's what the Bear Creek side charging upper looks like and a few details. The charging handle is .740" from the front of the bolt carrier, and it uses an ordinary 10-32 socket head screw going through the handle it's self. I don't know if Bear Creek actually makes these uppers or not, I've seen what looks like the exact same one unbranded from several retailers. I went with Bear Creek because I was ordering a barrel from them anyway and it saved on shipping.

I'm using a side charging 7.62x39 upper receiver and BCG unit from Bear Creek. It's inexpensive, and to my untrained eye looks to be decent quality. The problem is that the bolt carrier is too long since I don't have a buffer tube for it to slide into. Fortunately, the tail of an AR bolt carrier doesn't really do much to stabilize the bolt, all the tight clearance sliders where it contacts the upper receiver are on the front section. So out comes the cutoff wheel. A few whacks and some cleanup with a flap wheel, and our bolt carrier is a much more convenient size.

While it was all apart, I did some work on the firing pin too. Google says that 7.62x39 doesn't always fire reliably in AR platforms, especially the harder primer Russian steel cased stuff that I use. One fix is a heavier hammer spring, but that can negatively affect trigger pull. The other fix is to use an "enhanced" firing pin. What's the difference between the standard and enhanced firing pin? The stop shoulder is .010" shorter on the enhanced pin so that the firing pin protrudes just a little but further. If you don't have any size reference, .010" is about three sheets of paper thick. That little bit can make all the difference in the world on X39 ARs. Enhanced firing pins are cheap, but why spend $10 when I don't have to? The left side of the line is what we need to take off:

You don't even need any special tools to do this. You'd think a firing pin would be too hard to file, but they aren't. Just chuck it in a drill and have at it with a file. It's a 5 minute process.

While I had the grinder out, I cut off the trigger bit of the front trigger. It doesn't need to be cut all the way off, just far enough so that it doesn't hit the inside of the receiver.

Once I've verified that everything works and have uploaded my files, if you want make one yourself here's where the tail of the trigger is cut. The angle isn't super critical and I just used some scribed lines to cut it:

At the request of a guy I know, here's what the Bear Creek side charging upper looks like and a few details. The charging handle is .740" from the front of the bolt carrier, and it uses an ordinary 10-32 socket head screw going through the handle it's self. I don't know if Bear Creek actually makes these uppers or not, I've seen what looks like the exact same one unbranded from several retailers. I went with Bear Creek because I was ordering a barrel from them anyway and it saved on shipping.

Friday, December 27, 2019

Don't let your dreams be dreams!

It might not look much different, but practicaly everything from the magwell back on my SCR lower has been changed. I lowered and reshaped the trigger guard so that the bottom is at the same level as the magwell for easier printing, I moved all the safety features from the left side to the right, and thickened up some areas for a stronger print. I also changed everything that needed to change for the lever trigger system from my last post.

I printed out the transfer lever and trigger, and to save time and filament I only printed the back half of the lower. I also trimmed the tail of the front trigger as necessary for the transfer lever with my dremel. I put it all together and much to my surprise, it actually works. Even with the printed parts, the trigger pull is short and crisp. It's a little heavy, but not much more than the original(and definitely less than my Uzi). Not pictured but the safety works too and is index finger selectable. It seems to work well enough that I'm going to leave them as printed parts for now. The only extra parts needed beyond the printed bits are a 3rd AR trigger pin, and a 1/8" pin for the transfer lever. I don't really have a good way to capture the rear trigger pin yet though(though for as often as it will likely ever come apart, it could just press fit into the plastic receiver if I don't come up with something better).

Here's how the parts fit together when cocked(minus a little bit of wobble because the pins are just kind of sitting in the tops of the holes):

Here's about how far everything moves when it's fired. The safety acts as an overtravel stop for the mechanism, and the original trigger spring is strong enough to reset everything when you let off the trigger.

I printed out the transfer lever and trigger, and to save time and filament I only printed the back half of the lower. I also trimmed the tail of the front trigger as necessary for the transfer lever with my dremel. I put it all together and much to my surprise, it actually works. Even with the printed parts, the trigger pull is short and crisp. It's a little heavy, but not much more than the original(and definitely less than my Uzi). Not pictured but the safety works too and is index finger selectable. It seems to work well enough that I'm going to leave them as printed parts for now. The only extra parts needed beyond the printed bits are a 3rd AR trigger pin, and a 1/8" pin for the transfer lever. I don't really have a good way to capture the rear trigger pin yet though(though for as often as it will likely ever come apart, it could just press fit into the plastic receiver if I don't come up with something better).

Here's how the parts fit together when cocked(minus a little bit of wobble because the pins are just kind of sitting in the tops of the holes):

Here's about how far everything moves when it's fired. The safety acts as an overtravel stop for the mechanism, and the original trigger spring is strong enough to reset everything when you let off the trigger.

Wednesday, December 25, 2019

I'm just going to lever this right here.

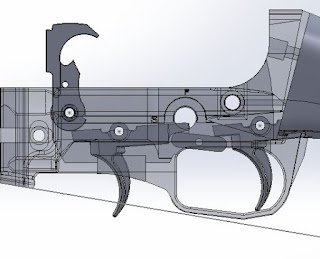

Here's my latest idea for my SCR trigger. Instead of a big long

extended trigger, it uses a short lever to transfer motion from the new

trigger to the tail of the original one. It uses a second AR trigger

with the tail cut off, but it could probably be a printed part(I'll try

it just to see). The lever can be made from a chunk of 1/4" square

stock, although it may be able to be printed too. The original AR

trigger needs some of the tail cut away for the lever but since there is

no disconnector in the way that's not a problem. Here you can see how

everything sits in the cocked position:

In this system, the rear trigger only needs to move 5°-6°, pretty much the same as a standard AR trigger. If I decide it works, I'll add more material around the lever pin so I've got a stronger print. I'm also going to reshape and relocate the trigger guard down a bit too so the lever won't protrude into it(and it will print better with less support if the bottom of the trigger guard is inline with the bottom of the magwell). The original trigger spring should reset everything. Here's how things move when it's fired. It still probably isn't going to be the world's greatest trigger pull, but it might be good enough.

In this system, the rear trigger only needs to move 5°-6°, pretty much the same as a standard AR trigger. If I decide it works, I'll add more material around the lever pin so I've got a stronger print. I'm also going to reshape and relocate the trigger guard down a bit too so the lever won't protrude into it(and it will print better with less support if the bottom of the trigger guard is inline with the bottom of the magwell). The original trigger spring should reset everything. Here's how things move when it's fired. It still probably isn't going to be the world's greatest trigger pull, but it might be good enough.

Tuesday, December 24, 2019

Stocking up.

I did some more work on my SCR stock. Not so geometric shapes like this are hard for me to do, it's not really something Solidworks was made for and I'm learning a lot as I go. I actually printed two more stock sections in the past few days. I got the first one off the printer and thought "Geez, this doesn't really feel different than my first attempt." And that's because I printed the same original test file again...oops. So then I printed the right one. It's much better and is a much more comfortable grip and easier/shorter trigger reach. It still needs more work as the base of my thumb sits uncomfortably against where the main section of the stock meets the grip portion. It's hard to show the difference, but here are the two versions together showing how much lower the grip section of the new one is. This one is also printed in Marble filament because I think that's what I want to use for the final stock/handguard prints. I live in WI after all, and winter is a thing we generally do pretty well.

For ease of use, I chose to dovetail the stock onto the receiver. That should give me a nice strong connection while only needing one small bolt to hold it in place. The dovetail also gives me a lot more solid material in the area where the lower is most likely to break in use. If need be, I can add a hole or two in that area to JB Weld in some steel reinforcing rods too. You can see how it slides on here:

For ease of use, I chose to dovetail the stock onto the receiver. That should give me a nice strong connection while only needing one small bolt to hold it in place. The dovetail also gives me a lot more solid material in the area where the lower is most likely to break in use. If need be, I can add a hole or two in that area to JB Weld in some steel reinforcing rods too. You can see how it slides on here:

Sunday, December 22, 2019

The first of many

I got my first SCR type lower receiver printed. This print was done quick with minimal shell thickness and infill because I'm just checking fit and function, and is in no way shootable. I also printed out the grip chunk of the stock so that I could see how it felt in the hand. Even though I'm never going to attempt to fire this one, for legal reasons(namely the short section of test grip), this is a pistol receiver. After playing with it some, I've come up with a list of things to work on. First, I'm going to flip the safety lever to the other side. It's not thumb reachable on the left side, but is index finger reachable if the lever is on the right. Second, the grip is way too high. I've got average sized hands and while I can reach the trigger, it isn't really comfortable so I'm going to move the grip down and forward some. Speaking of the trigger, it does work, but as expected the pull is very long and creepy. I'll work on making something better for the next one.

Saturday, December 21, 2019

New project time.

So I saw a picture on the internet the other day of what appeared to be a 3D printed AR-15 based bolt action rifle with a traditional rifle stock and I got inspired. In reading some discussions about it, I became aware of the Ares/Fightlight SCR which is basically an AR platform but with a standard rifle stock and no pistol grip, and I decided I wanted one. Actual SCR lowers though are $600+ and I'm definitely not going to spend that much.

Good thing I have a 3D printer. I'll just make my own. I'm not going to try to make a fully printed rifle, I'll use an off the shelf upper. The plan so far is to make a printed lower/stock, and use an off the shelf upper receiver and BCG. This will be a straight pull bolt action rifle, so even though it uses AR parts, I won't need a gas system or buffer tube(the buffer tube is the big one because without it I can shape the stock however I want). Since the back of the bolt carrier doesn't do much and is in the way on a rifle like this, I'll just cut it off. I'm going to make it in 7.62x39 because I already have plenty on hand so I'll be using an x39 sized BCG, barrel, and 10 round magazine.

In reading about it, I've learned that 3D printed ARs(and many plastic ones in general) break at the buffer tube tower. There's a lot of load on that area because of the bolt cycling, but since this will be a bolt action instead of semi-auto I don't need a buffer at all and it just needs to be strong enough to not break if I bonk it into something.

Next up was the trigger it's self. Obviously it has to move backwards a few inches to work with a standard rifle grip. My temporary solution is to just make an extender sleeve for it. This is still very much a work in progress and will probably be replaced with something better. For the time being I'm leaving the original trigger intact, I'll cut it down when I'm satisfied with how it works. Since this is a bolt action rifle, I don't need the disconnector so the new printed trigger extension slips right over the tail of the original one. I'll probably eventually make something with some kind of linkage, for now this is just a "see if it works" solution.

Here's where I'm at now. I relocated all the FCG parts, added reinforcement in some areas because this will be 3D printed, and I got started on drawing the stock. I got rid of the bolt catch too, it's not really needed anymore and the print will be stronger without it. The stock is dovetailed onto the lower, and will have a single attaching screw running into it. I'm not really happy with the stock yet but it's a start.

Good thing I have a 3D printer. I'll just make my own. I'm not going to try to make a fully printed rifle, I'll use an off the shelf upper. The plan so far is to make a printed lower/stock, and use an off the shelf upper receiver and BCG. This will be a straight pull bolt action rifle, so even though it uses AR parts, I won't need a gas system or buffer tube(the buffer tube is the big one because without it I can shape the stock however I want). Since the back of the bolt carrier doesn't do much and is in the way on a rifle like this, I'll just cut it off. I'm going to make it in 7.62x39 because I already have plenty on hand so I'll be using an x39 sized BCG, barrel, and 10 round magazine.

In reading about it, I've learned that 3D printed ARs(and many plastic ones in general) break at the buffer tube tower. There's a lot of load on that area because of the bolt cycling, but since this will be a bolt action instead of semi-auto I don't need a buffer at all and it just needs to be strong enough to not break if I bonk it into something.

Using a picture for reference, my new lower started as a pretty straight up copy of the SCR lower. But it wasn't really ideal in my eyes and wasn't suitable for 3D printing. So I started changing and modifying and tweaking things as I saw fit. The biggest change I made, other than the whole no pistol grip thing, was to move all the fire control parts up in the receiver .200" This allows for a shorter reach to the trigger and an overall shorter lower receiver. You can see here where the new location is compared to the standard AR, the new parts are the darker grey:

Next up was the trigger it's self. Obviously it has to move backwards a few inches to work with a standard rifle grip. My temporary solution is to just make an extender sleeve for it. This is still very much a work in progress and will probably be replaced with something better. For the time being I'm leaving the original trigger intact, I'll cut it down when I'm satisfied with how it works. Since this is a bolt action rifle, I don't need the disconnector so the new printed trigger extension slips right over the tail of the original one. I'll probably eventually make something with some kind of linkage, for now this is just a "see if it works" solution.

Here's where I'm at now. I relocated all the FCG parts, added reinforcement in some areas because this will be 3D printed, and I got started on drawing the stock. I got rid of the bolt catch too, it's not really needed anymore and the print will be stronger without it. The stock is dovetailed onto the lower, and will have a single attaching screw running into it. I'm not really happy with the stock yet but it's a start.

Saturday, December 7, 2019

That's that.

The Gun Kote Flat Black actually turned out to be pretty close to whatever finish Rock Island uses on their slides. I decided that the machining on the grips looked to good to cover, so I left them bare aluminum. I'm not super pleased with the finish on the frame though, so I will likely repaint it. It will do for now. As I said last time, all that's left is to put the slide on. It goes on like any other 1911 slide. The only other thing I did was put in an EGW shock buffer on the recoil guide to keep the steel slide from smacking the aluminum frame.

Who likes beauty shots?

Who likes beauty shots?

Friday, December 6, 2019

Closer

Getting close to the end now. My 1911-ish gun gets assembled like a 1911...ish. It's mostly like a 1911, but not quite. I mentioned that because of the integrated mainspring housing this thing is a bit fiddly to put together and has to be done in the right order, and here's how to do it.

Start by dropping in the trigger. Then the sear spring gets slid down into it's recess until the tab on the spring clicks into the slot in the magwell. To help keep it in place, a roll pin goes through the grip right behind the sear spring. The pin doesn't need to be a tight fit, the grips will hold it in place. The mag release can go in now too.

The next bit can be tricky the first time you do it. We have to install the mainspring into the housing. I use a screwdriver and the edge of the table to compress the spring. Gotta be careful not to slip and stab yourself.

Once the spring is compressed far enough, drop in the mainspring retainer pin through the hole in the MSH. It goes from the outside in, just the opposite of a standard 1911. It's only there as an assembly aid and will be removed later.

Next up is to put the frame on the grip section. Install the sear and disconnector in the frame, then slide it together. I use a hook to pull the sear spring back out of the way so that it can be put on the correct side of the sear.

Next up are the grips and the pin in front of the trigger guard. They should be a tight fit because you don't want any play between the frame and grip section.

Next is the hardest bit, installing the hammer. You've got to compress the mainspring enough to get the hammer lined up so you can drop in the pin. I've found that the easiest way is to make sure the hammer strut is lined up in the mainspring cap, then press hammer against the edge of the table with enough force to get the pin in. Get the angle just right, and it's not too bad. Once the hammer is in, you can pull out the mainspring retainer pin because it's not doing anything anymore.

Next is the grip safety. My printed GS slides straight into the back of the frame, then cock the hammer and install the safety lever like a standard 1911.

That's pretty much it, the frame is completely assembled. Check everything for proper operation, and then install the slide like you would in any other 1911. I'll add too that I'm using an EGW shock buffer on my recoil guide, just to keep the steel slide from smacking the aluminum frame.

Start by dropping in the trigger. Then the sear spring gets slid down into it's recess until the tab on the spring clicks into the slot in the magwell. To help keep it in place, a roll pin goes through the grip right behind the sear spring. The pin doesn't need to be a tight fit, the grips will hold it in place. The mag release can go in now too.

The next bit can be tricky the first time you do it. We have to install the mainspring into the housing. I use a screwdriver and the edge of the table to compress the spring. Gotta be careful not to slip and stab yourself.

Once the spring is compressed far enough, drop in the mainspring retainer pin through the hole in the MSH. It goes from the outside in, just the opposite of a standard 1911. It's only there as an assembly aid and will be removed later.

Next up is to put the frame on the grip section. Install the sear and disconnector in the frame, then slide it together. I use a hook to pull the sear spring back out of the way so that it can be put on the correct side of the sear.

Next up are the grips and the pin in front of the trigger guard. They should be a tight fit because you don't want any play between the frame and grip section.

Next is the hardest bit, installing the hammer. You've got to compress the mainspring enough to get the hammer lined up so you can drop in the pin. I've found that the easiest way is to make sure the hammer strut is lined up in the mainspring cap, then press hammer against the edge of the table with enough force to get the pin in. Get the angle just right, and it's not too bad. Once the hammer is in, you can pull out the mainspring retainer pin because it's not doing anything anymore.

Next is the grip safety. My printed GS slides straight into the back of the frame, then cock the hammer and install the safety lever like a standard 1911.

That's pretty much it, the frame is completely assembled. Check everything for proper operation, and then install the slide like you would in any other 1911. I'll add too that I'm using an EGW shock buffer on my recoil guide, just to keep the steel slide from smacking the aluminum frame.

The finish is in sight!

I'm not really a big fan of the two tone frame/slide look on 1911s, so I had to do something with my bare aluminum receiver. As luck would have it, I have a little bit of KG Gun Kote Flat Black left over from my Uzi. It's not a perfect match to the Rock Island slide, but it's close enough for now. Someday I might completely refinish both in the same color, but that day is not today. I really like Gun Kote. It's durable and it's just so easy to use. Prep your part, spray it on, and bake. It leaves a thin, hard, and fairly durable finish too so I sprayed the whole receiver, rails and all(300 rounds so far in my Uzi shows no wear at all on the Gun Kote where the bolt slides against the inside of the receiver). Here's my frame, fresh out of the oven.

Getting a grip, safely

In order to save an entire $30, I decided that I wanted to 3D print the grip safety on my 1911-ish. I figured that if nothing else, it's already a back up to the main safety so if it didn't work the gun would still be safe to use. I had a surprising amount of trouble with it, and it took several tries to get it right. Because of my integral mainspring housing, an off the shelf .250 radius 1911 GS would still work, but will need the little feet trimmed off the bottom in addition to all the standard fitting that you'd need to do so that the GS can be put on after the upper and lower parts are assembled. Here are all my attempts next to the steel part that came with my parts kit. Each one is just a little different than the previous version:

Friday, November 29, 2019

Oh yeah, it's all coming together.

Everything is fitted to the 1911-ish, so it's time to put it all together. Because the mainspring housing is integral with the printed grip section, assembly is a bit fiddly. It's not quire as straight forward as a standard 1911, but it's not too bad and it's not like it will have to come completely apart often. I'll make a "how to assemble" post at some point. I still need to reprint the grip safety in black too, I'll do that when I paint the frame. Anyway, here's how it looks all together:

All that's left is to test it. I got out my trusty "test stand", rope, and big tree to hide behind.

All that's left is to test it. I got out my trusty "test stand", rope, and big tree to hide behind.

Wednesday, November 27, 2019

Tube stakes

The last part that needs to be added to the 1911-ish frame is the plunger tube. It's pretty simple, you put it in, then mushroom over the posts inside the magwell. Before that can happen though, there needs to be someplace for the posts to mushroom into. To do that, I took my dremel, and cutting carefully with the bit extending through the post holes, added a countersink to the back side.

They sell a tool to stake the posts over with, and it works very well. I don't have that tool. What I do have is a lot of random stuff laying around. This little vice, for example, that I think I made in high school. I took a setscrew and added a point to it to mushroom the posts. I just hot glued the pointed setscrew onto the vice since it's a one time use tool.

I used some green Loctite retaining compound on the posts, then staked them over. The most important thing here is to find a perfectly sized drill bit to put into the plunger tube so that it won't collapse when you squeeze it. Is this the worlds greatest tool? No. Did it get the job done? Yes.

They sell a tool to stake the posts over with, and it works very well. I don't have that tool. What I do have is a lot of random stuff laying around. This little vice, for example, that I think I made in high school. I took a setscrew and added a point to it to mushroom the posts. I just hot glued the pointed setscrew onto the vice since it's a one time use tool.

I used some green Loctite retaining compound on the posts, then staked them over. The most important thing here is to find a perfectly sized drill bit to put into the plunger tube so that it won't collapse when you squeeze it. Is this the worlds greatest tool? No. Did it get the job done? Yes.

1911 feed ramp sanding jig

Here's a more detailed explanation of my 1911 feed ramp sanding jig. It should work for all full size 45acp 1911s. To use the jig, slide some 1/4" rod through the magwell so that it

rests against the mainspring housing edge of the magwell, with the

narrowest part of the jig on the feed ramp. Wrap the jig in sandpaper

and sand away. Look at the cutaway pictures to make sure that you have

the orientation right while sanding. Make sure that you DO NOT radius

the top corner of the ramp, it must be a sharp corner for proper

feeding. I shouldn't have to say this but DO NOT REMOVE ANY METAL FROM

YOUR GUN UNLESS YOU KNOW WHAT YOU ARE DOING. Metal is easy to remove

and hard to put back on. Oversanding the ramp can cause your gun to jam

and become unreliable, and it will need to be repaired by a

professional gunsmith. Here's a link to the 3D printed bit: https://www.thingiverse.com/thing:4006165

Ramped up

This is one of those small but very important 1911 detail things, the feed ramp. I chose to leave it completely uncut and in retrospect I should have just machined it along with everything else. But there is a library's worth of discussion and argument on what the "best" feed ramp angle should be and I wasn't sure how the barrel would fit so I put it off until later. And now it's later. After a whole lot of reading, I decided that despite all the discussion and arguments, it is not, in fact, rocket science. There are millions of these things out there from hundreds of companies, spanning over a century of manufacturing, and they can't all be the same. I chose the most commonly recommended ramp, at 31.5°. I started by laying out some guidelines where the limits of the ramp should be, the most important one is that it needs to be .030" from the throat of the barrel.

Not trusting myself to do an ultra precise angled setup on my little mill, I elected to do all the metal removal by hand. I can already feel the gun community shudder as I start attacking this with my Dremel.

I may look stupid, but I'm not dumb, and I'm not doing all of it with the Dremel. I'm just doing the roughest of roughing. The rest of it will be done with sandpaper. But how do you make a very precise angle with sandpaper? With a happy coincidence and a stupidly simple tool. You see, if you put a 1/4" rod through the magwell so that the back of it rests on the MSH side and the front lays on the feed ramp, it ends up being exactly 31.5°. If you then have a 7/16" diameter circle tangent to where it contacts the ramp, you have the exact diameter you need for the feed ramp. I checked everything in Solidworks, and it all works out perfectly. I made my tool with some 1/4" rod, and a 3D printed sleeve. I put a center line on it so I could be sure it stays straight up and down while being used.

Wrap the sleeve in sandpaper, hold the frame in something secure, and have at it. I taped off as much as I could to keep from getting everything scuffed up.

I sanded using progressively fine sandpaper up to 400 grit, and stopped when I hit the barrel setback line I had scribed.

Then I hit it with some Mother's Mag and Aluminum polish to shiny it up.

I don't know how accurate it actually is, but it feeds very well with my dummy rounds. We'll have to wait to see how it works with actual bullets.

Not trusting myself to do an ultra precise angled setup on my little mill, I elected to do all the metal removal by hand. I can already feel the gun community shudder as I start attacking this with my Dremel.

I may look stupid, but I'm not dumb, and I'm not doing all of it with the Dremel. I'm just doing the roughest of roughing. The rest of it will be done with sandpaper. But how do you make a very precise angle with sandpaper? With a happy coincidence and a stupidly simple tool. You see, if you put a 1/4" rod through the magwell so that the back of it rests on the MSH side and the front lays on the feed ramp, it ends up being exactly 31.5°. If you then have a 7/16" diameter circle tangent to where it contacts the ramp, you have the exact diameter you need for the feed ramp. I checked everything in Solidworks, and it all works out perfectly. I made my tool with some 1/4" rod, and a 3D printed sleeve. I put a center line on it so I could be sure it stays straight up and down while being used.

Wrap the sleeve in sandpaper, hold the frame in something secure, and have at it. I taped off as much as I could to keep from getting everything scuffed up.

Then I hit it with some Mother's Mag and Aluminum polish to shiny it up.

I don't know how accurate it actually is, but it feeds very well with my dummy rounds. We'll have to wait to see how it works with actual bullets.

Subscribe to:

Posts (Atom)